Ms. Laura Zhang

Hong Kong, Macao and Taiwan & Overseas Visitors

| Phone | +86 10 5867 7189 |

|---|---|

| Fax | +86 10 5867 7126 |

| wenting.zhang@hjtexpo.com | |

| Address | Room 2003, Building A, Timecourt, Chaoyang District, Beijing |

Exhibitor Profile

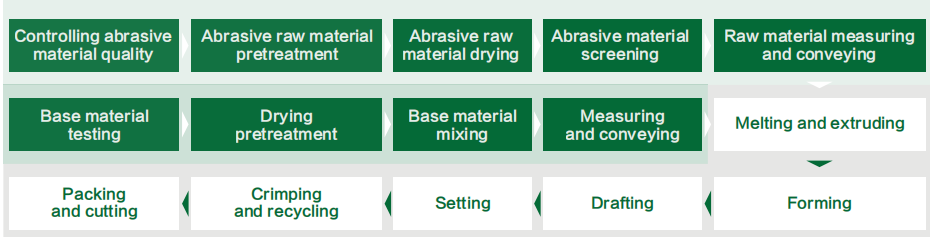

Originated in 1985, Tai Hing is one of the largest monofilament manufacturers in China, specializing in providing various high quality monofilament products, such as PA6/66/612 nylon filament, PP, PET, PBT tapered filament etc. With the factory area of more 20,000 square meter, Tai Hing has 25 modern monofilament production lines and more than 400 tons monthly production capacity.

With its products spanning across 12 industries and cooperating with over 35 countries as well as thousands of well-known international brands, Tai Hing pledges its commitment to a continued refinement in its craftsmanship. Succeed in becoming the epitome of exquisite quality and craftsmanship, the Group is recognized by ISO9001, ISO14001 and ISO45001. All filament products are certificated by RoHs, PAHs and REACH etc. Besides, innovative patent testing method for filament smoothness and dryness achieves the excellent filament tufting effect.

Product Overview

Abrasive Filament GrindFil Introduction

What’s GrindFil Abrasive Filament?

GrindFil abrasive filament is made of high quality nylon 612/610/6 filament and it is combined with silicon carbon/aluminium oxide grinding sand.

GrindFil has stable chemical resistance feature of nylon and bending recovery strength, which adapts to various kinds of environment, such as high & low temperature environment and dusty environment. With strong grinding ability, GrindFil is applied in twist brush, strip brush, belt brush, disc brush, roller brush, cup brush. Besides, GrindFil is also applied in wooden grinding, steel polishing, metal finishing, glass grinding and ceramics grinding industries.

The whole body of GrindFil, including its outer surface, cross-section and inner core, is randomly distributed by grinding sand to form rough, hard and tiny edges and corners. When the brushes are driven by the industrial machine at high speed, GrindFil scratches and rubs the metal surface densely, processing the procedures of finishing, polishing, deburring, sharpening and removing the oxide layers etc. GrindFil can keep outstanding surface finishing effect for a long time, which refers to the flexible grinding processing and it does not destroy the original size of workpieces.

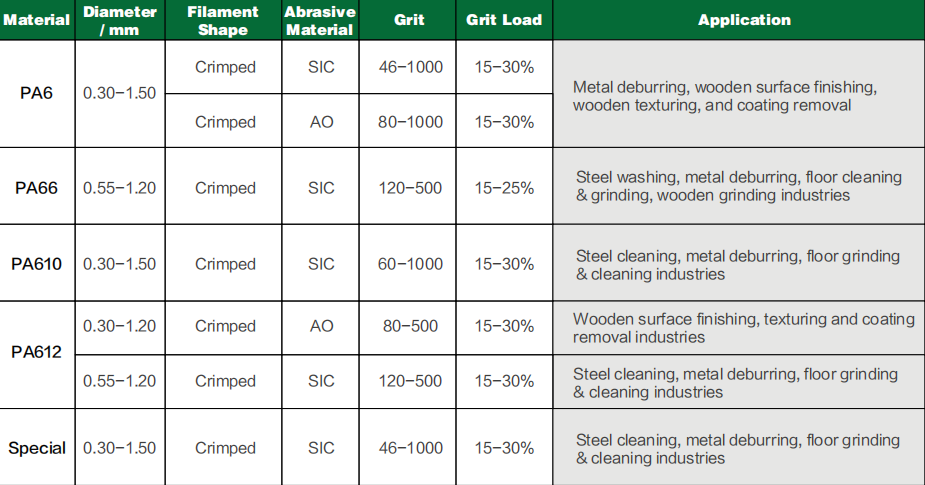

GrindFil Abrasive Filament Specification

GrindFil Performance

(1)Abrasive material grit load can be tested by ash test

According to the international standard measurement method of 【ISO 3451-1:1997】, we conduct ash test on GrindFil to determine whether the grit load of abrasive filament meets the standard.

(2)Tensile strength assessment: non-stop filament tufting effect

Outstanding tensile performance of GrindFil ensures that there is no filament breaking situation happening during the tufting process and steel plate grinding process.

(3)Softness and hardness assessment: moderate softness and hardness

The bending strength of GrindFil is effective to clean and polish workpieces without causing any damage to the steel surface.

(4)Resilience performance assessment: fatigue resistance performance

Nylon base material has excellent resilience performance. GrindFil always keep straight after use. The monofilament bending recovery rate of GrindFil exceeds 30% after tested by rebound test.

CIBRUSH 2023

China International Brush Making Industry Exhibition (CIBRUSH) is one of the largest international and professional brush industry exhibitions in the world. It focuses on the theme of “Brush Making is Getting Smarter” to show the latest products, trends, and technologies in the brush industry. Don’t miss it!

Click here for full list of exhibitors:

https://www.cibrush.com/en/index/visit/exhibitorsandproducts

Visitor Pre-registration: https://bj3.infosalons.com.cn/reg/CIB23SZ/registeren/start

Contact us:

Hong Kong, Macao and Taiwan & Overseas Visitors

| Phone | +86 10 5867 7189 |

|---|---|

| Fax | +86 10 5867 7126 |

| wenting.zhang@hjtexpo.com | |

| Address | Room 2003, Building A, Timecourt, Chaoyang District, Beijing |

Please browse vertically for better experience.